Hi Pollution Monitoring In Cement Industry!.

.jpg)

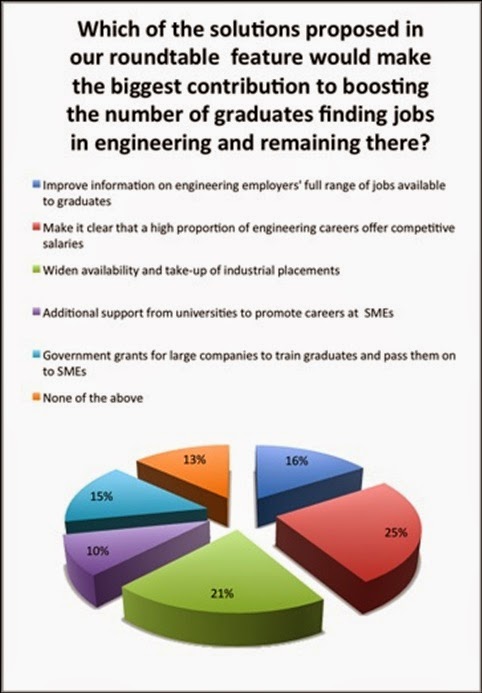

The rising use of waste based fuels in the cement industry, both for economic and Environmental objectives, combined with the strengthening of air emission regulations around the world is pushing many operators to face a wider list of pollutants to monitor this, with associated costs.

The design of appropriate solutions meeting local regulation is the key to maximize the cost benefit of the fuel while maintaining good relationships with local authorities and populations.

.jpg)

Besides the usually requested parameters, like SO2, NOx, CO, total particulate matter, and NH3, additional parameters can also be measured such as HCl, HF, Dioxins & Furans (PCDD/PCDF), Mercury (Hg) and VOC/TOC.

The monitoring of each gas pollutant, when required, can pose specific difficulties, but in general keeping the cost low means trying to operate a multi components analyzer able to measure all of them, except Dioxins & Furans and Mercury which requires very specific technologies and dedicated sampling devices.

Various manufacturers have developed a broad range of analyzers and sampling systems dedicated to meet cement operator needs according to their local regulation.

Some of these solutions are described below:

The MIR 9000H developed by Environnement S.A (France) is a new generation of heated NDIR analyzer able to simultaneously measure traditional components such as NOx, SO2, CO, CO2 and O2, in addition to H2O and pollutants like NH3 and HCl, representing a very cost effective, turnkey solution.

This analyzer was designed to be operated without any chiller, drying membrane, or catalytic oven, allowing the flues gas directly into the measurement cell without any kind of disturbance.

The entire system being heated to 180°C (~360°F), no condensation can occur even in extremely wet conditions with up to 40% moisture.

This analyzer’s robust design is particularly suited to demanding wet stack gas mixtures, including those with potentially high NH3, HCl and HF content. Indeed, this analyzer is completely immune to NH3, HCl and HF: both its integrity and its metrological performances being unaffected.

.jpg)

As a cost effective heated analyzer, the MIR 9000H is also an ideal solution for process control to monitor ammonia slips in SCR/SNCR processes.

In these processes, either ammonia or urea can be used. It is important to stress out that in the case of urea, MIR 9000H takes into account the N2O which is created as a by product. MIR 9000H can also cope with formaldehyde, a compound which can be produced with some types of fuels and cause problems to NDIR measurements.

For low SO2, HCl or NOx concentrations, the SEC-MIR9000 system combining an exclusive membrane based drying technology (sampling) and state of the art NDIR multigas analyzer remains the perfect solution.

It allows for the measurement of a wide range of pollutants, including also CO, CO2, HF and TOC, as well as N2O and formaldehyde for interference corrections purposes.

The SEC-MIR9000 system, while being technically speaking an extractive system, also exists as an in-sit setup (MIR IS).

Very low NOx concentrations can also be measured with a chemiluminescence CEMS bench, either as an option of an NDIR system, or as a standalone analyzer.

FTIR: Environnement S.A was the first company to introduce the FTIR technology for CEMS application and remains a leader.

This technology allows the monitoring of a wide range of pollutants, including SO2, NOx, CO, CO2, NH3, HCl, HF and VOC/TOC, with low measurement ranges, making it the ideal solution for the strictest regulations.

Dioxin is an increasing source of suspicion by neighbour populations in regards to waste or alternative fuels combustion.

The AMESA-D continuous sampler allows for a continuous coverage of dioxin emission and is already considered the standard for monitoring dioxins/furans around the world.

Beside the emissions of PCDD/PCDF there are other emissions of compounds which are not or not so easy to be monitored continuously.

E.g. mercury can be monitored continuously, but for plants with low concentrations in the range of µg/m3 the accuracies of the existing mercury CEMs depend very strong on the experiences and maintenance efforts of the operators.

Otherwise the results are not accurate enough. Additional the availability of such systems is restricted.

The continuous Hg Sorbent Trap Measurement System (STMS) AMESA-M represents a cost effective alternative to mercury analyzers, especially when the limit or detection is low and that complex and expensive technologies are necessary.

The system is based on the adsorption trap method described in the performance specifications 12B of the MACT standard for the continuous monitoring of mercury emissions and is suitable for nearly every application.

.jpg)

The AMESA-M system requires very low maintenance and is adapted to the different flue gas conditions and requirements given by the operators: its availability under difficult flue gas conditions could be kept by values of almost 100 %.